Welders In Leeds Can Be Fun For Everyone

Table of ContentsRumored Buzz on Welders In LeedsNot known Incorrect Statements About Welders In Leeds What Does Welders In Leeds Do?Rumored Buzz on Welders In LeedsMore About Welders In Leeds

Plastics welding also uses.heat to sign up with the products (although not in the case of solvent welding) and is achieved in three stages. To start with, the surface areas are prepared before heat and pressure is applied and, finally, the products are permitted tocool to develop fusion. Joining techniques for plastics can be separated into external or internal heating approaches, depending upon the exact process used. The materials to be joined go through a lot of pressure before a linear friction movement creates heat to bond the workpieces together. This is a fast process which allows wood to be joined without adhesives or nails immediately - welders in leeds. A connection in between completions or edges of 2 parts making an angle to one another of 135-180 inclusive in the region of the joint.

Getting My Welders In Leeds To Work

.

Joint in between 2 overlapping elements made by depositing a fillet bonded around the periphery of a victory part so regarding join it to the surface of the other component exposed through the hole. Bonded joint where the weld metal completely penetrates the joint with complete root fusion. In United States the preferred term is complete joint penetration weld (CJP, see AWS D1. 1). Weld in which the blend penetration is (welders in leeds).

purposefully less than full penetration. In the US the favored term is partial joint penetration weld( PJP). Metal added during welding, braze welding, brazing or appearing. All metal melted throughout the making of a weld and retained in the weld. The part of the moms and dad metal metallurgically impacted by the weld or thermal cutting heat, but not melted. Border in between the weld metal and the HAZ in a combination weld. Zone containing the weld metal and the HAZ. The surface area of a combination weld exposed on the side from which the weld has actually been made. Zone on the side of the first run outermost from the welder. Limit in between Related Site a weld face and the moms and dad metal or between runs. This is a really important function of a weld because toes are points of high tension concentration and frequently they are initiation points for different kinds of fractures( eg tiredness fractures, cold cracks ). Weld metal lying outside the plane joining the toes. Other non-standard terms for this function: reinforcement, overfill. the navigate here term reinforcement, although typically used, is unsuitable since any excess weld.

The smart Trick of Welders In Leeds That Nobody is Discussing

metal over and above the surface of the parent metal does not make the joint more powerful. In fact, the density considered when creating a welded element is the style throat density, which does not include the excess weld metal. Stratum of weld metal consisting of several runs. Various procedures are figured out by the energy source used,.

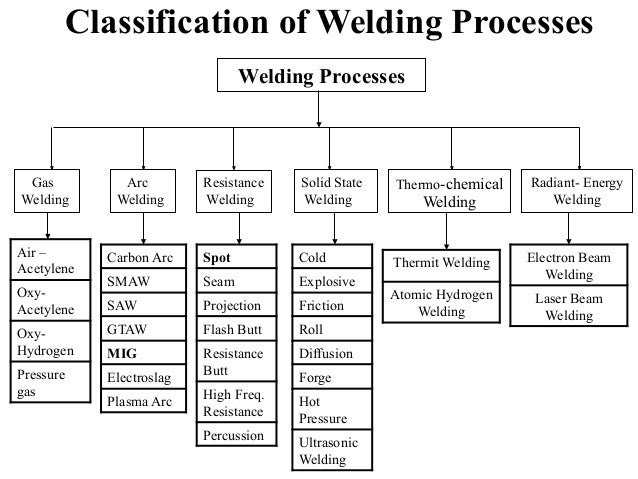

with a variety of different strategies available. Up until completion of the 19th century, create welding was the only technique used, but later processes, such as arc welding, have given that been developed. These methods generally utilize a filler product and are mostly used for joining metals including stainless steel, aluminium, nickel and copper alloys, cobalt and titanium. Arc welding processes are commonly used across industries such as oil and gas, power, aerospace, automobile, and more. Friction welding methods sign up with products using mechanical friction.

The mechanical friction creates heat which softens the products which blend to produce a bond as they cool. The manner in which the signing up with happens is dependant on the specific process used, for example, friction stir welding (FSW), friction their explanation stir area welding (FSSW), direct friction welding (LFW) and rotary friction welding (RFW).

Facts About Welders In Leeds Revealed

Friction is frequently used in aerospace applications as it is perfect for signing up with otherwise 'non-weldable' light-weight aluminium alloys. Friction processes are used throughout market and are also being explored as an approach to bond wood without making use of adhesives or nails. This blend signing up with procedure uses a beam of high speed electrons to join products.

Electron beam welding (EBW) is performed in a vacuum (with the usage of a vacuum chamber) to prevent the beam from dissipating. There are lots of common applications for EBW, as can be utilized to sign up with thick areas. This indicates it can be applied throughout a number of markets from aerospace to nuclear power and automotive to rail.

Being easily automated, the high welding speed at which this procedure can be performed makes it perfect for high volume applications, such as within the automobile industry. Laser beam welding can be carried out in air instead of in a vacuum such as with electron beam joining. This is a quick procedure which is commonly used in the vehicle industry.

The 3-Minute Rule for Welders In Leeds

Area welding usages heat delivered in between two electrodes which is used to a little area as the workpieces are clamped together. Seam welding resembles find welding other than it changes the electrodes with turning wheels to deliver a constant leak-free weld. TWI has among the most definitive varieties of services.

Lost your password? Please enter your e-mail address. You will receive a link and will create a brand-new password through e-mail.